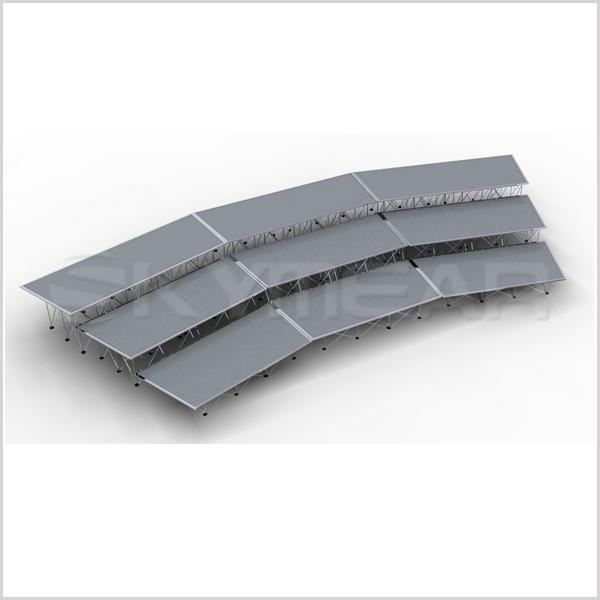

stage truss

How To Improve The Acid And Alkali Resistance Of Aluminum Alloy Trusses?

[2019-01-08]Because Aluminum Lighting Truss is made of high-strength aluminum alloy material 6061-T6, or 6082-T6, because aluminum itself is a more active metal component, it is easy to chemically react with the external acid and alkali, if it is long-term In the water, the aluminum component also reacts chemically in the water. In order to provide the stability of the performance of the aluminum alloy truss, the aluminum alloy truss is improved in acid resistance and alkali resistance, and the aluminum alloy truss is oxidized to make the surface attached. An oxide film prevents the corrosive effect of foreign substances on the aluminum alloy truss.

In order to overcome the defects of surface hardness and wear resistance of aluminum alloy and prolong the service life, surface treatment technology has become an indispensable part in the use of aluminum alloy. Metal oxide films alter surface conditions and properties such as surface coloration, improved corrosion resistance, enhanced wear resistance and hardness, and protection of metal surfaces. For example, aluminum is anodized, and the aluminum alloy is placed in a corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, and electrolysis is performed under specific conditions and an applied current. The aluminum of the anode or its alloy is oxidized, and a thin layer of aluminum oxide is formed on the surface thereof, and the thickness thereof is 5 to 20 μm. The anodized aluminum or its alloy improves the hardness and wear resistance. Our Stage Truss Systems will give you a favorable price, welcome new and old customers to buy at any time.

- Tel/WhatsAPP: +86 159 8664 2014

- E-mail: info@skymear.com

- Add: ROOM 1005,10/F,HO KING COMMERCIAL CENTER, 2-16 FA YUEN STREET,MONGKOK,KL HK

- Copyrights © Skymear Stage Truss

- All Rights Reserved

- Find Us