stage truss

What is the Parts of Aluminum Stage Lighting Truss Roof System?

[2022-05-22]What is the Parts of Aluminum Stage Lighting Truss Roof System?

Skymear Stage Lighting Truss product range include aluminum stage truss, staging truss, lighting truss, light truss, DJ truss, DJ trussing booth, DJ shows, exhibition truss, church sets, exhibition booths, start/finish lines, aluminum stages, display booths, trade show exhibit booths, trade show display, exhibit display booth, truss roofs, portable displays, portable stage, mobile stage, modular stage, removable stage, folding/foldable stage and many others. With 20 years’ experience, Skymear can offer the perfect solutions for entertainment industry, corporate events, concerts, theaters, churches, schools, exhibitions, indoor & outdoor events, and event architectural designs, fields of building constructions, advertisement market and sport events market.

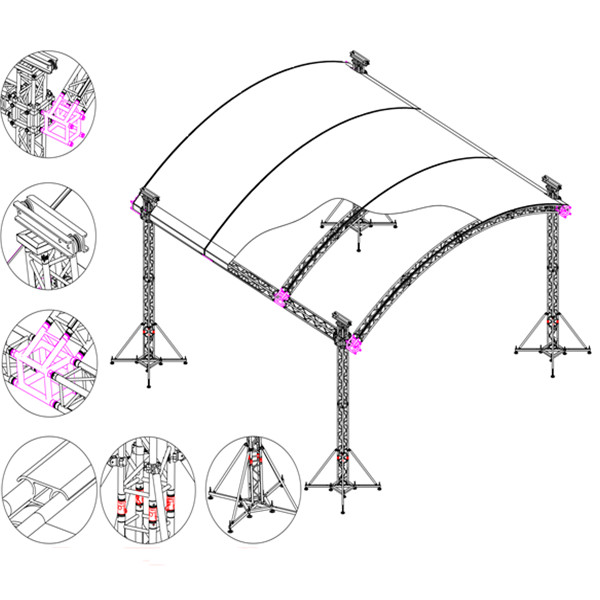

Today this article will discuss what stage lighting truss parts to make a complete truss roof system. Generally, the complete stage truss roof system can be divided into 3 parts: pillar, beam and ceiling.

● 1) Pillar

There are two types for the Pillars: Lifting system and Non-lifting system.

a) Lifting System

The lifting system is also called the ground support tower . The main accessories required for a pillar include: basement (including 4 outriggers), one 1M straight truss section, 4 hinges, straight truss sections nM (n=H-1), 1 sleeve block, 1 top section.

There is no hinges on the bolt tube truss, only the reverse head. The length of the reverse head is generally 1M, 1.2M and 1.5M according to the size of the beam. The beams of 300*300, 400*400, 450*450 use 1M reverse head, the beams of 400*600, 500*600 use 1.2M reverse head, and the beams of 520*760, 600*760 use 1.5M reverse head.

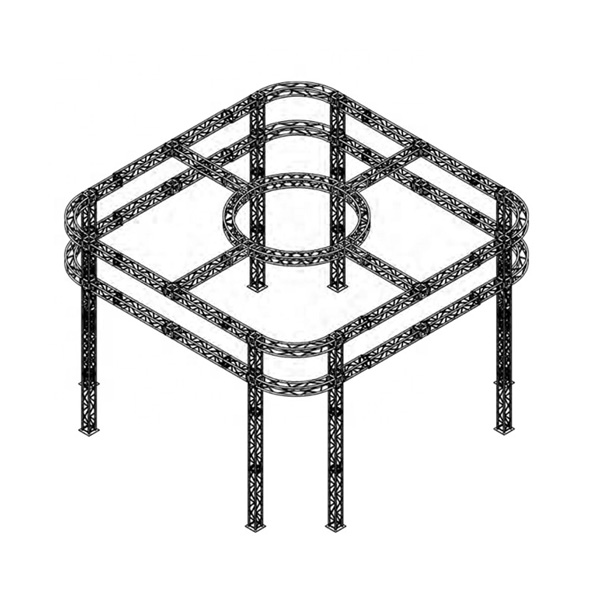

b) Non-lifting System

The pillars for non-lifting system are mainly connected by joints. They are used indoors or outdoors with a height of no more than 6M and a length and width of less than 10M. The special cases can be determined by the designers or purchasers. The non-lifting system are generally used in exhibitions.

● 2) Beam

The selection of stage lighting truss beams is generally based on the maximum span between the two pillars of the truss structure frame.

Spigot Truss:290*290, the max. span: 16M

390*390, the max. span: 18M

520*520, the max. span: 24M

Bolt Truss:300*300, the max. span: 14M

400*400, the max. span: 16M

450*450, the max. span: 18M

500*600, the max. span: 22M

600*760, the max. span: 26M

The above is the maximum span of each specification. Do not exceed the above size when equipping the truss roof system. But if customers requires that the audio equipment hung on the beam is too heavy, the specification of the shelf should be appropriately increased.

For example, The weight to be hung in the span of 16M reaches 800KG, and the load of the 290*290 rack is 450KG in 16M. Therefore, in the selection of beams, 390*390 should be selected as beams. The 16M span load of the 390*390 beam is 900KG. For specific load, please refer to the load table of each specification.

● 3) Ceiling

The beam segmentation methods:

If customers have no special requirements, the length of the quoted truss is calculated with the longest 3M, such as 14M truss consists of (3+3+3+3+2) segments.

If there are special dimensions required such as the bevel of front high and back low, and the bevel of the pitched top, etc., it is best to divide it by the designers. (If you are in a hurry to quote, you can add 1M to the straight edge size to quote) If the customer has a request, it should be divided according to the customer's request. The main reason for choosing 3M is to facilitate transportation for customers in the future.

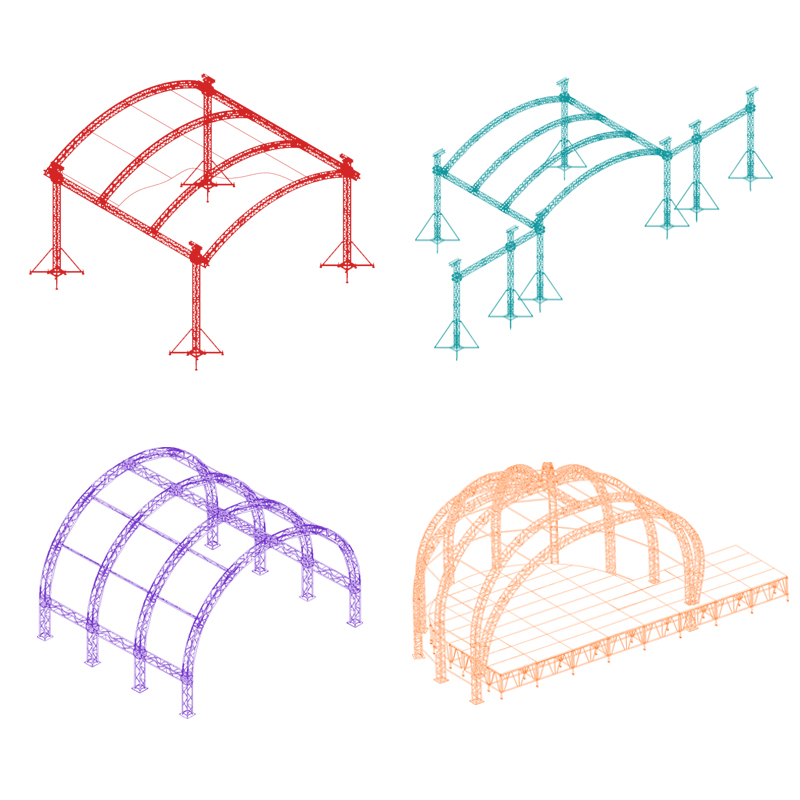

The truss frame with roof is mainly used for outdoor activities, sunshade and rain protection. Generally, it can be divided into flat roof, front high and back low roof, curved roof, pitched roof and other roofs as shown in the figure:

All the stage lighting truss parts together make a complete stage lighting truss roof system.

Previous: None

Next: What's the difference between stage truss aluminum raw materials

- Tel/WhatsAPP: +86 159 8664 2014

- E-mail: info@skymear.com

- Add: ROOM 1005,10/F,HO KING COMMERCIAL CENTER, 2-16 FA YUEN STREET,MONGKOK,KL HK

- Copyrights © Skymear Stage Truss

- All Rights Reserved

- Find Us