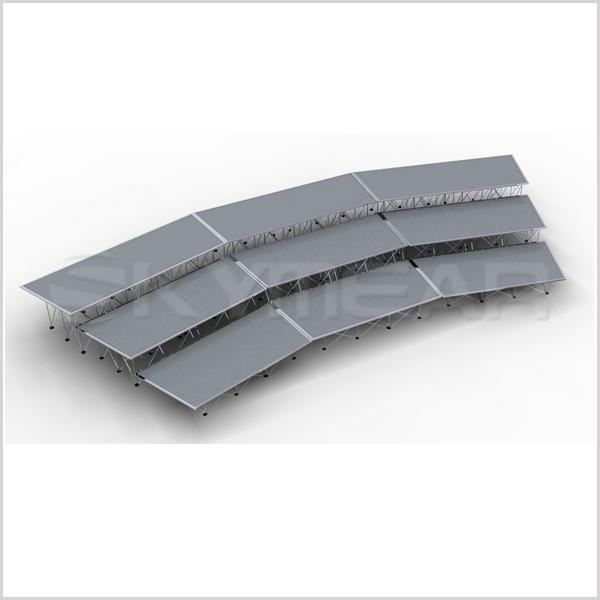

stage truss

How to Avoid Buying the Easily Deformable Stage Truss?

[2019-08-16]Why do consumers have feedback that the Stage Truss they buy are not durable, and the factors that affect the quality of the product are nothing more than these two points, one is raw materials, and the other is production technology? The truss production welding process plays an important role. The welding is to grasp the temperature and the position of the weld. Then when you buy a truss, where can you judge the quality of the welding process? As an Aluminum Trusses Supplier, let's share it with you.

Stage Truss

First, observe whether the solder joints are uniform and smooth. If there are some metal crucibles on the truss, it is probably because the welding is in order to grasp the proper temperature. If the temperature is too high, the liquefaction reaction will occur at one end, so deformation will occur.

Second, pay attention to the position of the welded joint. Every Aluminum Truss can be said to have undergone tempering before molding. The welds left by each weld are distributed in other places, such as the middle of the bottom weld. In order to achieve uniform force, the truss is easily deformed.

- Tel/WhatsAPP: +86 159 8664 2014

- E-mail: info@skymear.com

- Add: ROOM 1005,10/F,HO KING COMMERCIAL CENTER, 2-16 FA YUEN STREET,MONGKOK,KL HK

- Copyrights © Skymear Stage Truss

- All Rights Reserved

- Find Us