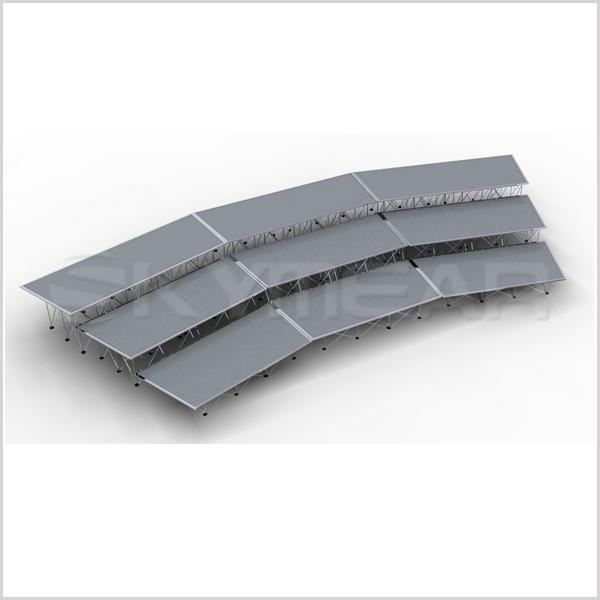

stage truss

How to choose the high-quality aluminum stage lighting truss?

[2022-06-05]With the development of the internet era, there are more and more lighting truss manufacturers to sell portable stages, aluminum trusses and other products through the internet channels in the performance industry. But after all, there are many drawbacks in the online channels. The online trade cannot allow buyers to truly see the scale of lighting truss manufacturers, product quality, and craftsmanship. This also gives some aluminum lighting truss manufacturers who do not pay attention to quality a loophole to manufacture the poor quality aluminum trusses, resulting in frequent performance accidents.

This also makes it particularly important for buyers to identify high-quality aluminum lighting trusses, especially in the current industry lack of an regulation, so the quality of aluminum lighting trusses must attract our attention, and we must choose high-quality, efficient and safe aluminum truss. It is necessary to fully understand the production process and material of the aluminum lighting truss. Also it is best to go to the manufacturer's production workshop for on-the-spot inspection.

Any product that can occupy a place in the market will always have its own unique feature. Of course, aluminum trusses are no exception. However, there are many types of trusses, among which aluminum alloys also have many different products, but the advantages they often have are the key to occupying the market. However, there are also good and bad aluminum alloy trusses in the market. So how to identify high-quality aluminum alloy truss?

First of all, in general, the high-quality aluminum stage lighting trusses are finely welded, and the welding lines are fish-scale-like, and the dimensions are accurate, and there will be no misalignment of screw holes or misalignment of trusses and accessories. But the poor quality aluminum alloy trusses are rough in welding, irregular in shape, ugly in solder joints. The solder joints are like a small hill, which is not beautiful at all.

Secondly, the high-quality aluminum stage lighting trusses are treated with acid, which shows bright silver, and is novel, elegant, and radiant. The poor quality truss has not been treated with acid, which shows that it is dull, earthy gray, ugly, and looks like an old antique.

Third, the high-quality aluminum alloy trusses are generally packaged in bubble bags to ensure that the products will not be worn during transportation; while the poor quality aluminum alloy trusses are packaged in plastic bags, which are easy to wear during transportation. Both ends of the main pipe of the high-quality aluminum alloy truss are welded with plugs, which will enhance the mechanical strength of the truss itself; while the main pipe of the inferior aluminum alloy truss is empty at both ends, which is neither beautiful nor high in strength and easily deformed when hit.

Finally, the planes at both ends of the high-quality aluminum stage lighting truss are ground by a grinder to ensure that the planes at both ends of the truss are flush; while the planes at both ends of the inferior aluminum alloy truss are not ground after welding, and they are not smooth, and the connection is also not smooth.

Previous: None

Next: What's the difference between stage truss aluminum raw materials

- Tel/WhatsAPP: +86 159 8664 2014

- E-mail: info@skymear.com

- Add: ROOM 1005,10/F,HO KING COMMERCIAL CENTER, 2-16 FA YUEN STREET,MONGKOK,KL HK

- Copyrights © Skymear Stage Truss

- All Rights Reserved

- Find Us