stage truss

Introduction of Aluminum Truss Roof System

[2016-12-23]In the performance industry, the aluminum stage truss or lighting truss comes in sectional lengths connected together to create longer spans or different shapes. And the longer spans or shapes finally constitute different roof truss systems. These roof truss systems are used to support lighting, audio and video equipment, which can be the best solutions for concerts, theaters, exhibitions, trade shows, dj display booth, and indoor & outdoor events, etc. This article is mainly about the introduction of the aluminum roof truss system in details, hoping customers can have better reference for the truss structures.

The complete aluminum truss roof systems can be divided into 3 parts: pillar, beam and ceiling.

● Pillar

There are two types for the Pillars: Lifting system and Non-lifting system.

a) Lifting System

The main accessories required for a pillar include: basement (including 4 outriggers), one 1M straight truss section, 4 hinges, straight truss sections, 1 sleeve block, and 1 top section.

There is no hinges on the bolt tube truss, only the reverse head. The length of the reverse head is generally 1M, 1.2M and 1.5M according to the size of the beam. The lighting truss beams of 300*300, 400*400, 450*450 use 1M reverse head, the lighting truss beams of 400*600, 500*600 use 1.2M reverse head, and the lighting truss beams of 520*760, 600*760 use 1.5M reverse head.

b) Non-lifting System

The pillars for the non-lifting system are mainly connected by joints. They are used indoors or outdoors with a height of no more than 6M and a length and width of less than 10M. The special cases can be determined by the designers or purchasers. The non-lifting aluminum truss roof systems are generally used in exhibitions.

The selection of beams is generally based on the maximum span between the two pillars of the truss structure frame.

Spigot Truss:290*290, the max. span: 16M

390*390, the max. span: 18M

520*520, the max. span: 24M

Bolt Truss:300*300, the max. span: 14M

400*400, the max. span: 16M

450*450, the max. span: 18M

500*600, the max. span: 22M

600*760, the max. span: 26M

The above is the maximum span of each specification. Do not exceed the above size when equipping the truss roof system. But if customers requires that the audio equipment hung on the beam is too heavy, the specification of the shelf should be appropriately increased.

For example, The weight to be hung in the span of 16M reaches 800KG, and the load of the 290*290 rack is 450KG in 16M. Therefore, in the selection of beams, 390*390 should be selected as beams. The 16M span load of the 390*390 beam is 900KG. For specific load, please refer to the load table of each specification.

● Ceiling

If customers have no special requirements, the length of the quoted truss is calculated with the longest 3M, such as 14M truss consists of (3+3+3+3+2) segments.If there are special dimensions required such as the bevel of front high and back low, and the bevel of the gold top, etc., it is best to divide it by the designers. (If you are in a hurry to quote, you can add 1M to the straight edge size to quote) If the customer has a request, it should be divided according to the customer's request. The main reason for choosing 3M is to facilitate transportation for customers in the future.

The truss frame with roof is mainly used for outdoor activities, sunshade and rain protection. Generally, it can be divided into flat roof, front high and back low roof, curved roof, pitched roof and other roofs as shown in the figure:

a) Front high and back low roof

This type roof truss generally use the length and width of less than 12M*10M. The truss crossing dimension used is generally 290*290mm. The height difference between the front and back is generally 1M (B1-B2 size), and the highest height F1 is required to be below 10M. If the size is larger than this size, it is recommended that customers choose other solutions

The middle truss sections of the roof to support canvas are generally using the ladder truss less than 6M in width. The width of larger than 6M must use the triangle or square truss sections. The connection method is generally using the single clamps to fix and lock onto the beam. Generally, the ladder truss beam needs two clamps and the triangle truss beam needs four clamps. The interval between the ladder and triangle truss is required to add a row every 2M.

b) Pitched Roof Truss System

The Pitched Stage Truss Roof is the most commonly used solution for shading and rain protection. The span of this structure can reach even 24M according to the beams and pillars changing, like the photo A above. The maximum span can reach the size of A in the 24M picture. Generally, the span of 290*290mm is below 16M, the span of 400*400mm is below 20M, and the span of 520*520mm is below 24M. The triangle side of the pitched roof ceiling frame generally needs 2 slop connectors, and one four-side connector. The connecting way for slop connector and beams is to use the swivel clamps.

The middle truss sections of the roof to support canvas are generally using the ladder truss less than 12M in width. The width of larger than 12M must use the triangle or square truss sections. The connection method is generally using the single clamps to fix and lock onto the beam. Generally, the ladder truss beam needs two clamps and the triangle truss beam needs four clamps. The interval between the ladder and triangle truss is required to add a row every 2M.

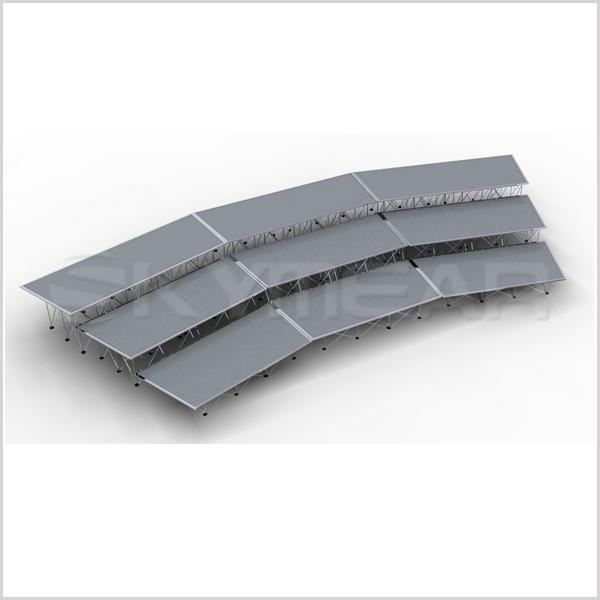

c) Arched Roof Truss System

As to all the roofing truss system, if the load is too large, it is recommended to pull the wire rope on the back, both sides and the top of the truss frame. The diameter of the wire rope should be at least 10mm. Each truss basement needs to load around 1000kg, so it can be placed some cement bricks, sandbags, water bags and other heavy objects on top. This can resist wind load of below level 7(V=16M/s). If raining, it need to deal with the accumulated water on the roof in time. If the wind level exceeds 7 or the rain is too heavy, the activities should be stopped and the roof should be lowered to the lowest position.

- Tel/WhatsAPP: +86 159 8664 2014

- E-mail: info@skymear.com

- Add: ROOM 1005,10/F,HO KING COMMERCIAL CENTER, 2-16 FA YUEN STREET,MONGKOK,KL HK

- Copyrights © Skymear Stage Truss

- All Rights Reserved

- Find Us